Tutorial Membuat Robot Avoider

Komponen Yang Dibutuhkan

Hal pertama yang perlu kita lakukan adalah mempersiapkan komponen-komponen yang dibutuhkan. Tujuan dari pembahasan ini salah satunya adalah membuat robot semurah mungkin namun tetap dapat menjalankan fungsinya dengan baik. Yah, karna kantong saya terbatas, maka saya mencoba membuatnya semurah mungkin. Saya rasa temen-temen juga setuju dengan saya.. :)

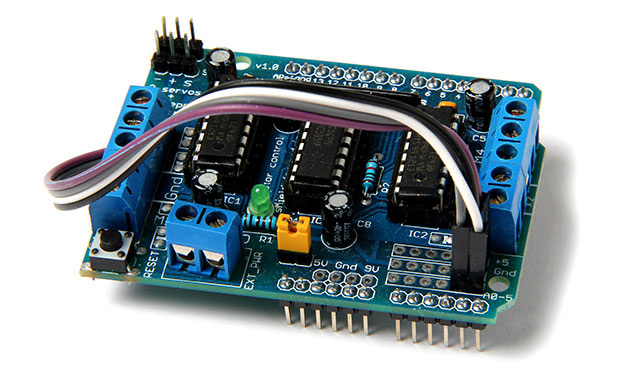

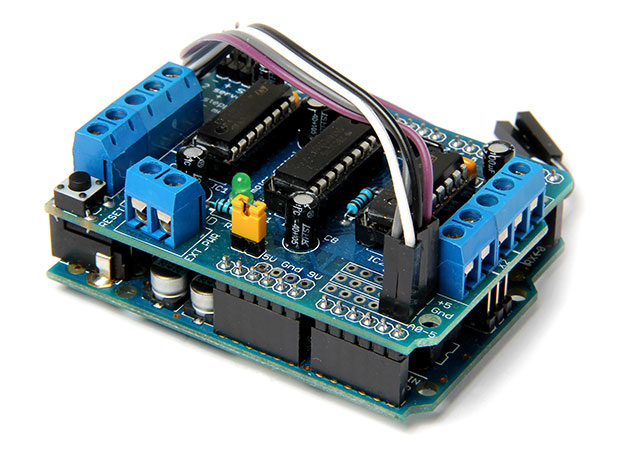

Lihatlah gambar-gambar komponen di bawah ini untuk daftar komponen yang kita butuhkan dalam membuat robot ini. Untuk alat-alatnya seperti obeng dan alat-alat potong standar aja imajinasiin oke..

Lihatlah gambar-gambar komponen di bawah ini untuk daftar komponen yang kita butuhkan dalam membuat robot ini. Untuk alat-alatnya seperti obeng dan alat-alat potong standar aja imajinasiin oke..

Blok Diagram

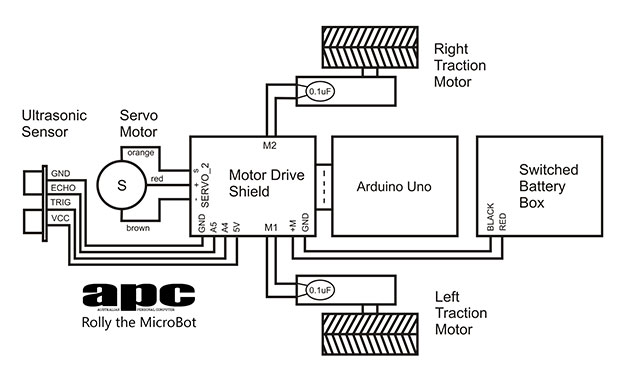

Kita akan lebih banyak membahas lebih banyak membahas lebih lanjut pada bagian-bagian berikutnya. Namun, sebelumnya kita akan melihat dan memahami dulu blok diagram dari Robot Penghindar Halangan ini. Blok diagram akan mempermudah kita dalam memahami bagaimana robot ini bekerja. Komponen yang ada dalam blok diagram di bawah ini yaitu Sensor Ultrasonik, Servo Motor, Motor Driver, Arduino Uno, DC Motor, dan Baterai.

Sensor Ultrasonik memberikan informasi jarak yang akurat sampai ketelitian centimeter. Nah, hasil bacaan sensor ultrasonik inilah yang akan menentukan apakah Robot akan berhenti atau mencari jalan yang lain untuk menghindari halangan yang ada pada jalurnya.

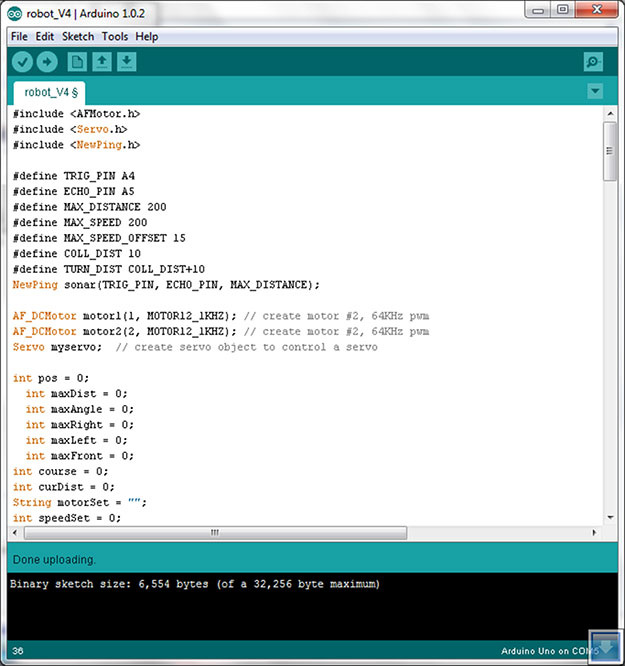

Data dari sensor ultrasonik akan diteruskan ke Arduino Uno kemudian, Arduino akan mengeksekusi program yang telah diupload ke mikrokontrolernya untuk mengendalikan putaran Motor DC. Oke, cukup untuk sedikit tentang teorinya, sekarang kita mulai saja untuk merakitnya..

Data dari sensor ultrasonik akan diteruskan ke Arduino Uno kemudian, Arduino akan mengeksekusi program yang telah diupload ke mikrokontrolernya untuk mengendalikan putaran Motor DC. Oke, cukup untuk sedikit tentang teorinya, sekarang kita mulai saja untuk merakitnya..

Langkah Pertama

Kita menggunakan papan pcb atau plastik sebagai body dari Robot Penghindar Halangan Ini. Rencananya, saya ingin membuat PCB Rangkaian Motor Driver langsung sebagai body dari robot kemudian, tapi karna saya sudah ada Driver Motor DC, kali ini kita gunakan plastik saja sebagai platform dari robot kita ini.

Badan robotnya saya buat dari plastik CD bekas. Kemudian, saya buat polanya sama seperti papan Arduino.

Tips : Ketika mengebor PCB/plastik, atur bor dengan kecepatan rendah terlebih dahulu. Jika sudah ada lubang atau tanda sedikit barulah menggunakan putaran yang lebih kencang. Untuk mata bor gunakan yang 3mm atau 4mm.

Badan robotnya saya buat dari plastik CD bekas. Kemudian, saya buat polanya sama seperti papan Arduino.

Tips : Ketika mengebor PCB/plastik, atur bor dengan kecepatan rendah terlebih dahulu. Jika sudah ada lubang atau tanda sedikit barulah menggunakan putaran yang lebih kencang. Untuk mata bor gunakan yang 3mm atau 4mm.

Langkah Kedua

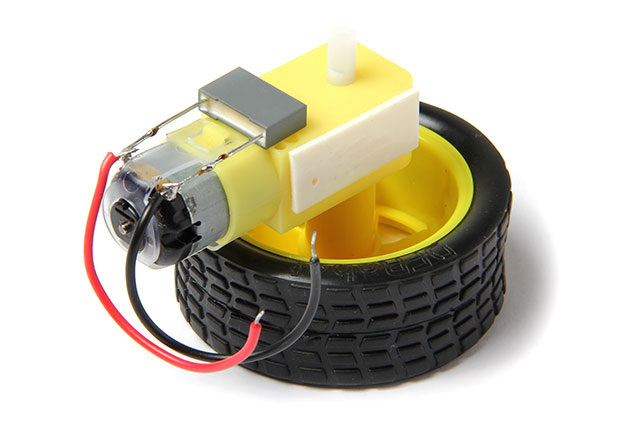

The 0.1uF capacitors have to be soldered across the motor connections and help reduce electrical noise in the circuit, otherwise the Arduino gets a bit cranky. Provided you use ceramic or Mylar capacitors, they have no polarity so just solder one leg to each motor connection tag and do so on both motors. Try to lay the capacitors flat against the yellow gearbox body to keep things neat.

You also need to solder onto the connection tags the wires that go to the Motor Drive Shield. Try attaching them to the capacitor leads if you’re not confident to get everything soldered at the motor connection points. These motors have a D-shaft and wheels that simply press onto the shaft. Use just enough pressure to get the wheel on. After that, cut a small strip of double-sided padded tape, peel back one layer and press it against the motor gearbox, which will mate with the base.

Tip: The motor connection tabs are quite weak, so don’t bend or force them. And take no more than five seconds to solder the capacitors or you might cause the motor connection to break.

You also need to solder onto the connection tags the wires that go to the Motor Drive Shield. Try attaching them to the capacitor leads if you’re not confident to get everything soldered at the motor connection points. These motors have a D-shaft and wheels that simply press onto the shaft. Use just enough pressure to get the wheel on. After that, cut a small strip of double-sided padded tape, peel back one layer and press it against the motor gearbox, which will mate with the base.

Tip: The motor connection tabs are quite weak, so don’t bend or force them. And take no more than five seconds to solder the capacitors or you might cause the motor connection to break.

Langkah Ketiga

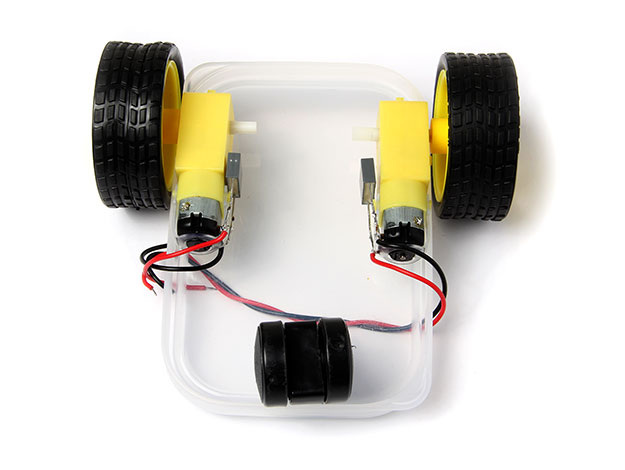

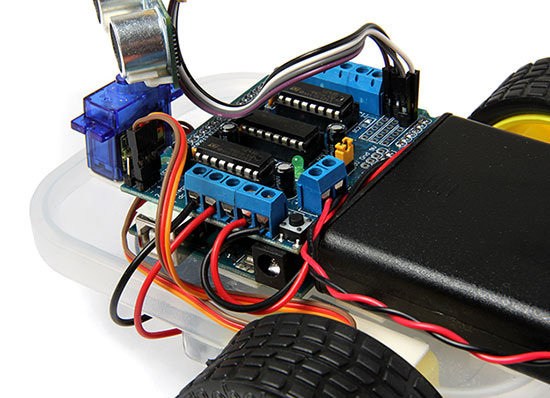

Install the two DC motors to opposite sides of the base using the double-sided tape. Get the motors as close to the edge as possible to allow the wheel free movement

Langkah Keempat

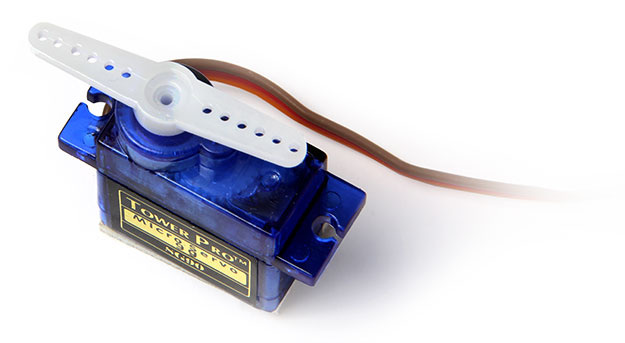

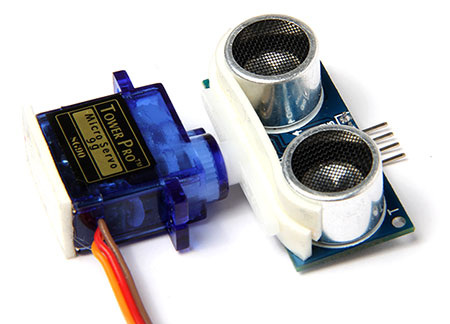

The little SG90 servo motor gives our microbot a neck so it can spin the ultrasonic sensor on its axis. The servo motor itself should come with an accessory pack of attachments called horns. Use the two-sided arm and press it onto the servo motor shaft. You’ll probably need to use a bit of force to get it on the first time, but try not to use too much.

Langkah Kelima

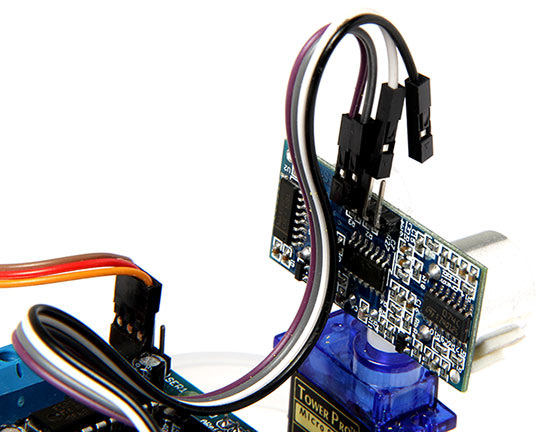

The Motor Drive Shield provides the extra drive power to control the DC motors. It also provides connection for the servo motor and the ultrasonic sensor, for which you’ll need four male-to-female DuPont wires. If you bought a bag of 40 moulded wires, peel four of them off and carefully solder the male ends to the Motor Drive Shield. Solder one wire to the +5V rail, one to the GND pin and one each to analogue pins A4 and A5 down in the bottom right-hand corner. Check the block diagram for pin assignments

Langkah Keenam

The Motor Drive Shield has a series of pin headers on the bottom of the board — these align with the headers on the top of the Arduino. Align the pins and press the shield onto the Arduino board.

Langkah Ketujuh

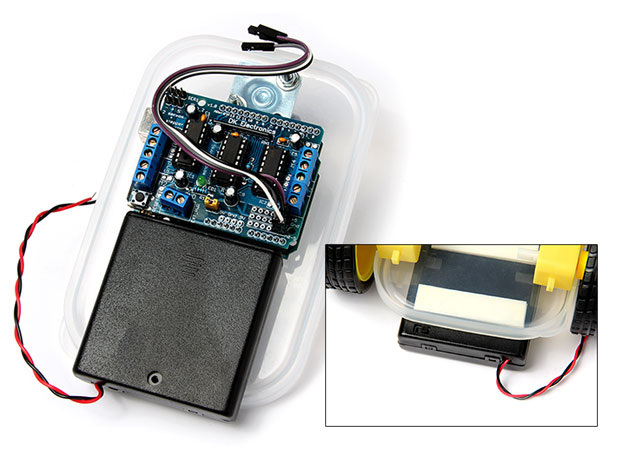

Grab some more double-sided padded tape and add it to the bottom of the Arduino board and the battery box. Note that you want the bottom of the battery box stuck to the base so you can easily remove the top of the box and get at the batteries. Make sure you orient the battery box so the slide switch hangs over the back edge to make it easier to operate. Stick the battery box down first, ensuring the switch overhangs at the back and align the Arduino/shield stack next to it. Depending on the size of the lip of your food container, you may need two layers of padded tape to get the height right.

Langkah Kedelapan

Next, add some double-sided padded tape to the top of the ultrasonic sensor — use enough to wrap around the sides of the sensors for added stick. Make sure the four header pins are pointing up and press the sensor against the servo horn. Add some more tape to the bottom of the servo motor and install it at the front of the base near the caster wheel mounting holes. Connect the servo motor power cable to the ‘SERVO_2’ port at the top-left of the Motor Drive Shield. The orange wire should go to the ‘s’ header pin.

Langkah Kesembilan

Next, connect the female ends of the DuPont wires to the ultrasonic sensor pins. The A5 wire should go to the ‘echo’ pin and A4 to the ‘trigger’ pin. I used a loosely wrapped rubber band to keep the wiring neat and allow enough play to move freely.

Tip: The HC-SR04 ultrasonic sensor is connected to the Arduino’s analogue inputs, although we first program them into digital inputs in our source code.

Tip: The HC-SR04 ultrasonic sensor is connected to the Arduino’s analogue inputs, although we first program them into digital inputs in our source code.

Langkah Kesepuluh

Connect the battery to the EXT_PWR screwblock, but make absolutely sure you get the polarity right or you’ll blow up everything before you start. One of the screw terminals in that block should be labelled +M or +; the other GND. Whichever battery holder you choose, the red wire goes to the +M screw terminal and the black wire to the GND terminal.

The DC motor wires connect to the M1 and M2 screwblocks. The left-side motor wires go to the M1 terminals; the right-side motor goes to the M2 block (you should be able to make this out looking at the silk screening on the top of the Motor Drive Shield.) Don’t worry too much about polarity at this stage — wait until you get to the test run stage and we’ll sort out any polarity issues then.

The DC motor wires connect to the M1 and M2 screwblocks. The left-side motor wires go to the M1 terminals; the right-side motor goes to the M2 block (you should be able to make this out looking at the silk screening on the top of the Motor Drive Shield.) Don’t worry too much about polarity at this stage — wait until you get to the test run stage and we’ll sort out any polarity issues then.

Langkah Kesebelas

Before you install any batteries, check, recheck and triple-check your wiring now. The servo motor header, the ultrasonic sensor and battery box connections must be correct. The DC motor wires are less important.

Tidak ada komentar:

Posting Komentar